Workshops - Learning Events

Our Workshops move people from ‘Not Knowing’ to ‘Doing’ - turning knowledge into action.

Interactive, fun, engaging - our methods deliver ‘Twice the Learning in Half the Time.’

No ‘Death by PowerPoint’ - Learn by playing, exploring and creating your own understanding.

Image with thanks to Celemi International. We are accredited to deliver Celemi simulations ‘Apples & Oranges’ and ‘Livon Lite’

-

Lean Fundamentals - Create 'Flow', Reduce Waste and Improve Profit

‘Lean Fundamentals’ immerses you in a Lean journey in the captivating ‘Plug Factory’ simulation. Learn about One-Piece Flow, Seven Deadly Wastes, Line Balancing, ‘Takt’ time, and Kanban, and much more. A lot of ground is covered in this fun, fast-paced simulation. Your people become alive to the possibilities of ‘Lean’ making a real difference.

One-Day | On-Site | 6-24 Learners | Cost $1,500 (+gst,+t&a)

-

Lean for Office, Sales and Service

‘Lean for Office, Sales and Service’ immerses your people in a Lean journey in our ‘Global Megacorp’ simulation.

Learn about the 7 Customer Wastes, the 14 Office Wastes, Process Mapping, ‘Swimlanes’, Kanban and the Visual Workplace. We show how ‘Lean’ makes a real difference in an Office, Sales and Service environment.

One-Day | On-Site | 8-24 Learners | Cost $1,500 (+gst,+t&a)

-

Introduction to Process Picture Maps

Learn about Process Picture Maps (PPM’s) in this 2-hour introduction to PPMs.Improve your SOP’s and learn how every PPM is a Mini-Improvement Program.

The ‘Peg Board Factory’ and ‘Satellite Launcher’ simulations teach how to improve work-flow, improve process layout, and then capture your improved processes in PPM’s.

2 hrs | On-Site or Zoom| 8-24 Learners | Free - email Glen to book a workshop

-

Kanban and 'Just-in-Time' - Reduce Inventory and Lower Cost

Learn how to implement a ‘Just-in-Time’ Kanban system in our dynamic, interactive workshop - “Kanban at Acme Flux & Gizmo Factory.” Learn how to move from ‘Push’ to ‘Pull’, lower inventory, deliver-in-full, on-time to customer demand, build customer-supplier relationships, reduce inventory and dramatically reduce cost.

One-Day | On-Site | 6-24 Learners | Cost $1,500 (+gst,+t&a)

-

Value Stream Mapping - Eliminate Bottlenecks and Increase Productivity

A Value Stream is all the actions to bring a product or service into the arms of the customer.

This workshop teaches Value Stream Mapping concepts and symbols (day 1), and we construct a real ‘Current State Value Stream Map’ to identify improvements (day 2).

Two-Days | On-Site | 6-24 Learners | Cost $2,800 (+gst, +t&a)

-

5S/6S for Safety, Quality & Productivity

5S or 6S (which is 5S+Safety) is the most widely used of the ‘Lean’ toolbox - and the most widely misused!

Learn the real foundations of 5S from Taichi Ohno, of Toyota Production System fame, and see how ‘good’ 5S/6S improves workplace organisation, productivity and efficiency.

One-Day | On-Site | 6-24 Learners | Cost $1,500 (+gst,+t&a)

-

Problem Solving and Root-Cause Analysis

‘Problem-solving’ is a sadly undeveloped skill. Before we put in a solution, we must focus on facts, check our assumptions, see what is really happening.

We identify all of your current problems, identify opportunities for improvement and introduce A3 Thinking and Visual Projects to begin creating solutions.

One Day | On-Site | 6-24 Learners | $1,500 (+gst,+t&a)

-

Levelled Production - Improve Productivity and Efficiency

‘Levelled Schedules’ are the single most important thing you can implement for greater productivity and efficiency. This Implementation Program uses ‘Green Stream Thinking’ to analyse your sales/production data and develop ‘Levelled Schedules’ to dramatically improve productivity and lower cost.

Multi-Day | On-Site | Customised | $POA

-

Quick Change-Overs - Deliver in Full, On Time

‘Quick Changeovers’ utilises ‘Green Stream Thinking’ and our ‘Action Mapping’ methodology to capture actual changeovers to analyse for improvement.

Our ‘Quick Changeover’ workshop is a specialised/advanced program for production operators, maintenance and engineering staff.

Multi-Day | On-Site | Customised | $POA

-

Visual Project Execution - Successful Improvement Projects

The goal of everything we deliver at Performance Frameworks is for your people to implement meaningful change that delivers results. A crucial skill, often overlooked, is Project Management.

Our Visual Project Execution framework is a clear, visual and effective methodology that works.

One Day | On-Site | 6-24 Learners | $1,500 (+gst,+t&a)

-

Strategy & Execution - 'Hoshin Kanri' - Achieving Results

Strategy and Execution are crucial – everyone in the business must play their part. In this workshop we explore the importance of gaining ‘Strategic Alignment’ to the overall company strategy, engage in ‘Collaborative Visioning’ to develop a strategic plan for your team and department, and how to effectively execute your strategic plan.

One Day | On-Site | 6-24 Learners | $1,500 (+gst,+t&a)

-

Statistical Process Control

This workshop teaches how to construct, implement and analyse ‘X-bar R Charts’. Your team learn about variation, the Normal Curve, Common and Assignable causes.

We introduce Demings’ famous ‘Red Bead Experiment’, how Statistical Process Control supports Six-Sigma and cover Ishikawa’s Seven Quality Tools.

One-Day | On-Site | 8-24 Learners | Cost $1,800 (+gst,+t&a)

-

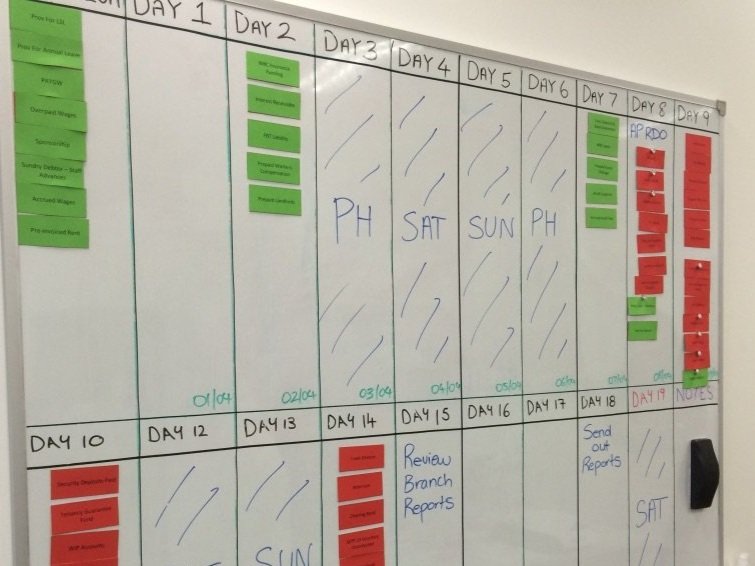

The Visual Workplace

This workshop introduces Visual Workplace, which helps everyone to know what is happening, what needs to be done and the problems and issues we are solving to create a better workplace.

A visual workplace is a self-ordering, self-explaining, self-regulating and self-improving work environment — where what is supposed to happen does happen, on time, every time, day or night — because of visual solutions.

One-Day | On-site | 6-24 Learners | Cost $1,500 (+gst,+t&a)

-

Change Leadership

This workshop explores ‘Change’ in the context of your Lean journey. We begin by discussing the difference between ‘Change Leadership’ and ‘Change Management’ – and why we need both for effective change.

We explore why people generally resist change – and why this is perfectly rational and logical. We will explore why change is so often difficult – and how we can engage everyone, even those who appear opposed to our proposed change.

Your Change Leadership learning event will be customised to meet your specific challenges and support the culture and change you wish to implement.

One-Day | On-Site | 6-24 Learners | Cost $1,500 (+gst,+t&a)

-

Innovation - Kaikaku

In the past, organisations could survive even with very limited amounts of innovation. They could focus on providing quality products and simply update them to a level that maintains their competitiveness in the market.

However, the innovation cycle has now accelerated. You need more than good products to survive; they require innovative processes, and management that can drive down costs and improve safety, quality, delivery, cost, safety, sustainability and productivity.

Your Innovation Learning Event will be customised to meet your specific challenges and deliver the Innovation Culture you seek to achieve.

One-Day | On-Site | 6-24 Learners | $1,500 (+gst,+t&a)