Execution Programs

Many Consultants focus on ‘Tools.’ We focus on People getting Results.

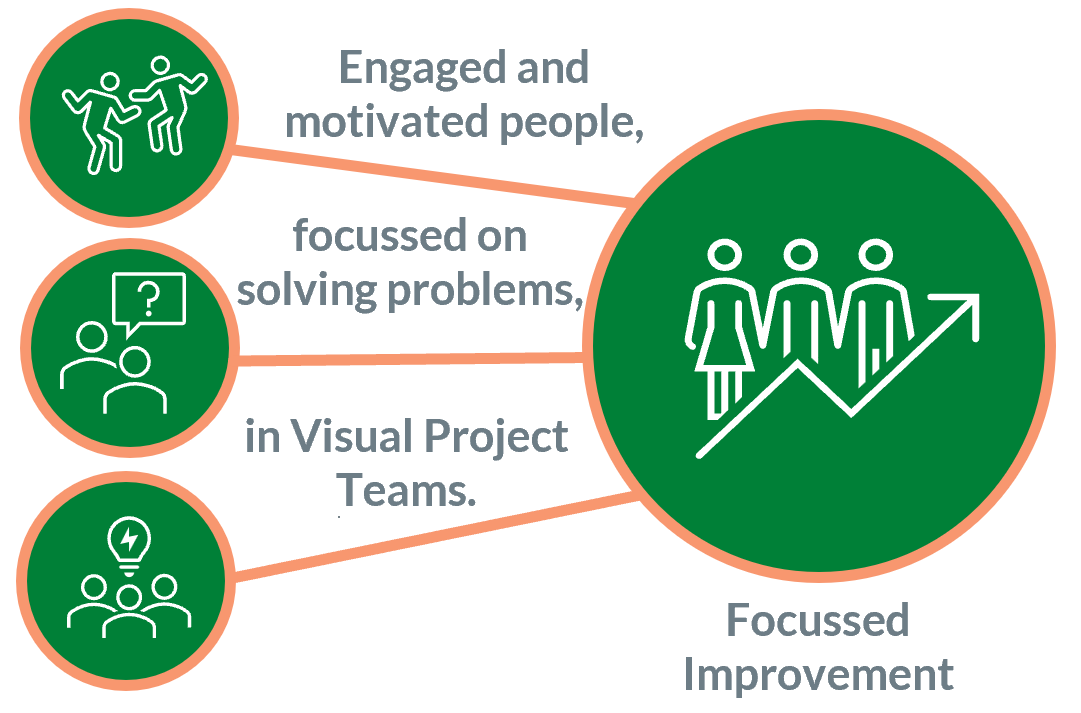

‘Focussed Improvement’

“To the man with a hammer, every problem is a nail.”

Some consultancies specialise in Visual Management, some always start with 5S, and some ‘Value Stream Map’ - whatever is their ‘thing.’ They introduce a tool, then look for an application.

At Performance Frameworks we prefer to start with people.

We engage and motivate. We respect the great work they do and celebrate their achievements. We create new ways of thinking in our simulations and games to envisage even better future performance.

We inspire teams to identify problems and barriers in creating their better future. Our Visual Project Teams approach empower teams to achieve results and create their better future.

Levelled Production -

Deliver In Full, On Time

The Foundation for Continuous Improvement

A ‘Levelled Schedule’ is critical in achieving dramatic improvements in all Key Performance Indicators. Improve Productivity. Reducing Lead Times and Cycle Times.

Reduce Work-in-Process. Slash Inventory Levels of Green Stream products. Apply Kanban, create Flow and Pull. A Levelled Schedule is an essential ‘precondition’ for effective In-Process Kanban.

We will show you how to ‘Level Production’.

‘Make Work Visible’ -

Analyse and Improve your Processes

‘Going to Gemba’ and ‘Go See’ is the first crucial step to improving processes. But what if you could capture a whole shift of production in Time-Lapse video? What if you could sit with your teams, watch a production shift, or even a whole day, and brainstorm better ways?

You can. ‘Action Mapping’ captures the Gemba over a few hours, or a whole shift, from up to four different locations at once.

Use the power of ‘Action Mapping’ to improve productivity, eliminate ‘Seven Wastes’, do Quick Changeovers and much, much more.

Quick Changeover:

Deliver in Full, On Time

Make ‘Every Product, Every Interval’ for your Levelled Schedule

‘Quick Changeovers’ are an essential component of a ‘Levelled Schedule.’ Quick Changeovers’ are also critical in moving to ‘Every Product, Every Interval’ to reduce inventory and respond to customer demand.

Our ‘Quick Changeover’ Implementation Program incorporates workshops, our ‘Action Mapping’ to capture a time-lapse of your current changeovers, and then a Project Plan to reduce changeover time through ‘Single Minute Exchange of Die’ (SMED) techniques.